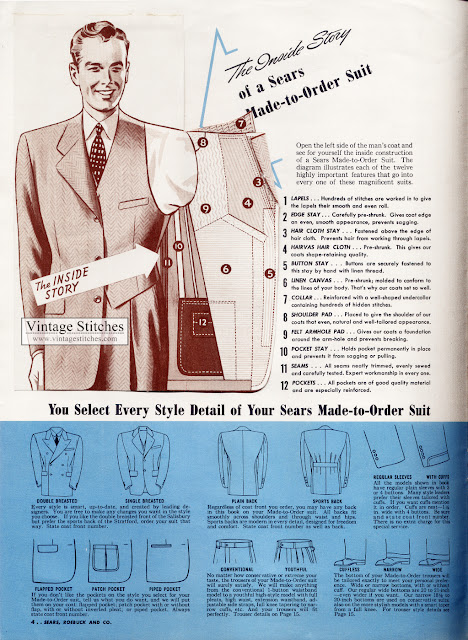

The Inside Story

. . . of a Sears Made-To-Order Suit.

|

|

Sears Made to Order Clothes for Men and Young Men, Spring & Summer 1941 Jessica Hartman Jaeger Collection | VintageStitches.com |

1. Lapels - Hundreds of stitches are worked in to give the lapels their smooth and even roll.

2. Edge Stay - Carefully pre-shrunk. Gives coat edge an even, smooth appearance, prevents sagging.

3. Hair Cloth Stay - Fastened above the edge of the hair cloth. Prevents hair from working through lapels.

4. Hairvas Hair Cloth - Pre-shrunk. This gives our coat shape-retaining quality.

5. Button Stay - Buttons are securely fastened to this stay by hand with linen thread.

6. Linen Canvas - Pre-shrunk; molded to conform to the lines of your body. That's why our coats set so well.

7. Collar - Reinforced with a well-shaped undercollar containing hundreds of hidden stitches.

8. Shoulder Pad - Placed to give the shoulder of our coats that even, natural and well-tailored appearance.

9. Felt Armhole Pad - Gives our coats a foundation around the arm-hole and prevents breaking.

10. Pocket Stay - Holds pocket permanently in place and prevents it from sagging or pulling.

11. Seams - All seams neatly trimmed, evenly sewed and carefully tested. Expert workmanship in every one.

12. Pockets - All pockets are of good quality material and are especially reinforced.

This is pretty much the "inside story" of any well made and high quality, traditionally tailored suit coat.

Additional scans can be viewed in my Flickr album--

https://www.flickr.com/photos/vintagestitches/albums/72157630081660716

Comments

Post a Comment